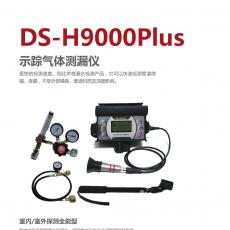

- 美国 MONITOR HMI 重锤式料位计(人机界面)

详细信息

加工定制:是 品牌:美国 MONITOR 型号:HMI 材质:塑料 类型:重锤式物位计 测量范围:45m 测量精度:1mm 供电电源:220V AC 防护等级:IP66 美国 MONITOR HMI 重锤式料位计(人机界面)

品牌:MONITOR名称:MONITOR HMI重锤式料位计(人机界面)

简介:MONITOR重锤式料位计人机界面多功能 HMI 控制 SMU 操作、模拟输出激活(如果配置),显示测量和计算数据,和执行/显示系统和传感器失效诊断。 该重锤式料位计通过了 CE 1010 认证,防止电磁波的干扰和产生;MONITOR重锤料位计人机界面独特的背光设计,NEMA 4 等级的外壳,适用于 -20℃的低温环境,自动、人工或自动/人工操作模式, HMI根据用户的输入数据计算和显示料位,体积值、重量值和百分量(参考体积/重量计算的使用),显示英制或公制单位包括英尺、米、磅、千克、立方英尺、立方米、蒲式耳(美制或英制)、加仑、升、美吨或英吨和公吨,显示物料名称(12个英文字符以内)。

MONITOR重锤式料位计人机界面多功能 HMI 控制 SMU 操作、模拟输出激活(如果配置),显示测量和计算数据,和执行/显示系统和传感器失效诊断。该重锤式料位计通过了 CE 1010 认证,防止电磁波的干扰和产生;MONITOR重锤料位计人机界面独特的背光设计,NEMA 4 等级的外壳,适用于 -20℃的低温环境,自动、人工或自动/人工操作模式。除此之外,MONITOR重锤式料位计人机界面还有以下特点:

□ MONITOR重锤式料位计人机界面有16个通道可选

□ 与带RS485功能的SUM连接

□ LCD显示料位高度、体积、百分比美国 MONITOR HMI 重锤式料位计(人机界面)

MONITOR 重锤式料位计人机界面参数:

防护等级:NEMA4

认证:CE1010

适用:-20℃的低温环境

显示单位:英制或公制

MONITOR 重锤式料位计人机界面选型表

美国 MONITOR HMI 重锤式料位计(人机界面)

测量原理应用指南

SILO PATROL® SE INVENTORY MONITORING SYSTEM

Weight and Cable-Based “Smart” Level Sensor Is Unaffected By Material Composition

Level Sensor Uses Innovative Hall Effect Technology To Maximize Application Reliability By Effectively Regulating Power To Motor Under Varying Load Conditions

Industry–Best Measurement Resolution Of 1/100’

(0.12”; 3mm)Measuring range up to 150 feet (46m) for powder bulk solids material levels in bins and silos. (Works for some liquid & slurry applications with optional ball float plumb bob)

Virtually Maintenance-Free

Split-Compartment Enclosure Isolates Electronics And Measurement Optics From Process Material

Uniquely Designed Wiper Seal Compartment For Fast, Easy Servicing or Replacement iI Necessary

RS-485 Pulse And Analog Sensor Output Available

Hazardous Location Sensor Version

Wireless Sensor Interface Solutions

PC-Based Inventory Solutions (Click Here)

HMI2 Local Operator Interface Option (Click Here)

Auxiliary System Outputs Available (Click Here)

HMI2

OPERATOR INTERFACE CONTROL CONSOLE

Two sensor networks with a capacity of 16 sensors each (32 total) are provided to

communicate with SiloPatrol® SMU SE “Smart” RS-485 cable-based level sensors and/or the Flexar® guided wave radar sensors.Calculate and display values for level, volume, weight and percent with data input from the user

Enhanced volume and weight calculations have the ability to include the additional

amount of material contained in the roof sections of steep silo roofs below the sensor mounting locationAutomatic, Manual or Auto/Manual operating modes provide versatility for SMU SE

Displays real-time measurement updates provided by Flexar sensors

Set-up parameters for Flexar can be modified using the HMI2

Built-in 16 point strapping table

Flexible display of data in English or Metric units including feet, meters, pounds, kilograms, cubic feet, cubic meters, U.S./British bushels, gallons,

liters, tons, metric tonnesProgrammable 12-character alphanumeric name for labeling vessel contents.

Unique back-lit display ensures visibility in low light conditions

Universal AC power supply accepts 100-240V AC power

Controls analog outputs and/or relay outputs when using the optional Auxiliary Output Enclosure - AOE (Click Here)

-

自定义内容

-

产品搜索

下载中心

-

DS-Multi1 双模两用测漏仪 使用说明书 V1

-

DS-Multi2 双模两用测漏仪 使用说明书 V1

-

韩国大成 DS-50d (蓝d)数字式漏水检测仪 说明书

-

韩国大成DS-500Plus 漏水检测仪 操作说明书 CN

-

美国Spectrum 2265FS土壤电导率仪 使用说明书

-

爱尔兰RWS渗漏寻检仪 中文操作手册

-

英国Land Model 4200烟尘颗粒物监测仪

-

英国Land Model_4200+ 在线式激光粉尘检测仪

-

ULZC型重锤式料位计2018年 说明书

-

JESMAN ActiGraph 体动记录仪-wGT3X-BT

-

以色列 BlueI HG 202 水卫士

-

英国DUSTMATE NASA-2手持式粉尘仪

-

英国离子 FALCO法尔考VOC 在线监测仪(本安型)

-

HAL-HFX105 高精度手持甲醛检测仪

-

瑞典 Haglof CI 坡度仪

-

扫一扫,手机浏览

扫一扫,手机浏览